Adhesive 566.0 PUR grey KLEIBERIT

Do you have any questions?

Contact us and we will help youElastic polyurethane adhesive - sealant

| Product | Price for vnt (be PVM) | Quantity (vnt) |

|---|---|---|

|

Adhesive 566.0 PUR grey KLEIBERIT:

0.7 kg

Package size:

0.7 kg

|

- |

Thank you, your request has been sent

KLEIBERIT Supracraft 566 is a permanently elastic, quick-drying, one-component polyurethane adhesive and sealing compound. Curing occurs by reaction with moisture. The adhesive is IMO-certified for use in shipbuilding.

Application:

- Bonding metal brackets for double flooring

- Bonding and sealing of metals, vanished sheets, wood, plastics, natural stone, ceramics, and masonry

- Bonding in shipbuilding (complying with IMO FTPC Part 5 and Part 2)

Benefits:

- Single component

- Paintable

- Non-corrosive

- Vibration absorption

- Remains resilient

KLEIBERIT 566 technical data:

Base: Polyurethane

Hardening: by reacting with moisture

Density: ~1.45 g/cm3

Available colours: black, white, and light grey

Consistency: paste-like

Temperature resistance: -40 °C ... +90 °C (trumpalaikis iki +120 °C)

Klijavimo temperatūra: +10 °C ... +35 °C

Time to film formation (open time): ~60 minutes (depending on ambient humidity and temperature)

Setting rate: at 23°C and 50% relative humidity: 3mm per day.

Resistance to chemicals:

- Long-term: water, salt water, sewage, aqueous cleaners, weak acids and alkalis.

- Short-term: petrol, alcohol, mineral oil, grease.

- Non-resistant: thinners and organic acids, concentrated acids and alkalis, alcohol, varnish thinner.

Mechanical properties:

Hardness according to DIN 53 505 (28 days at 23°C and 50% relative humidity): About 45 according to Shore A

Ultimate tensile strength (53 504): Approx. 1.8 N/mm2

Elongation at break (53 505): >600%

Tear resistance: >6N/mm2

Ability to regain its original shape (DIN EN ISO 7389): >70%

Allowable deformation (DIN EN ISO 10563): About 15%

Water vapour permeability (DIN EN ISO 53122): Approx. 2.000

Bonding:

Read the safety data sheets before bonding.

The parts to be glued must be clean and free of grease. We recommend using cleaner KLEIBERIT 820.0 to clean parts. (Make sure that the cleaner does not damage the materials). Smoked timber, such as smoked oak, must be ammonia free. Timber with a high oil content, such as exotic timber, must be checked before gluing. KLEIBERIT SupraCraft 566 is applied to one of the surfaces to be glued. If necessary, until a film is formed, the adhesive can be puttied with a trowel. Squeeze the parts together and lock in place.

Cleaning: Work tools must be cleaned immediately with a cleaner KLEIBERIT 820.0. Hardened adhesive can only be removed mechanically.

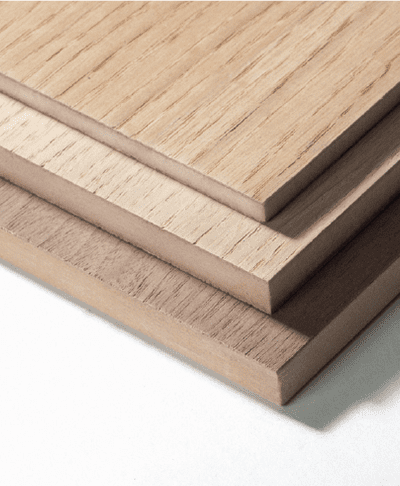

Veneered panels

Veneered panels  Decking boards

Decking boards  Cladding boards

Cladding boards  Decking and cladding accessories

Decking and cladding accessories  Adhesive melt

Adhesive melt  Contact glue

Contact glue  Assembly adhesive

Assembly adhesive  PUR Glue

PUR Glue  PVA Glue

PVA Glue  Cleaners and other accessories

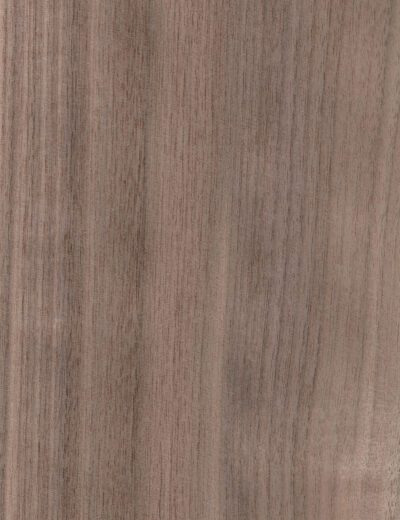

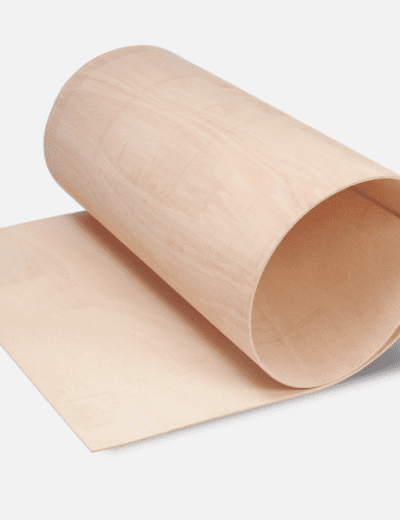

Cleaners and other accessories  Natural veneer

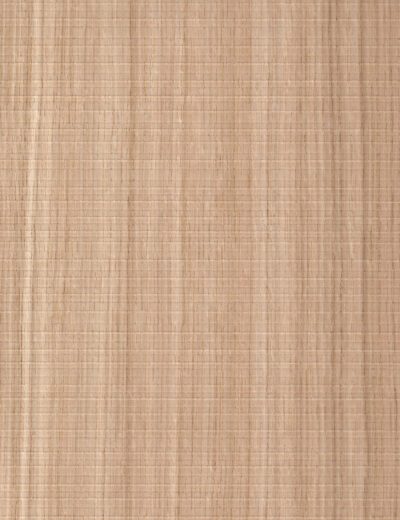

Natural veneer  Fine line veneer

Fine line veneer  South American wood spieces

South American wood spieces  African wood spieces

African wood spieces  American wood spieces

American wood spieces  Asian wood species

Asian wood species  European wood spieces

European wood spieces  Interior and exterior painted siding

Interior and exterior painted siding  Blockboard

Blockboard  MDF

MDF  CB

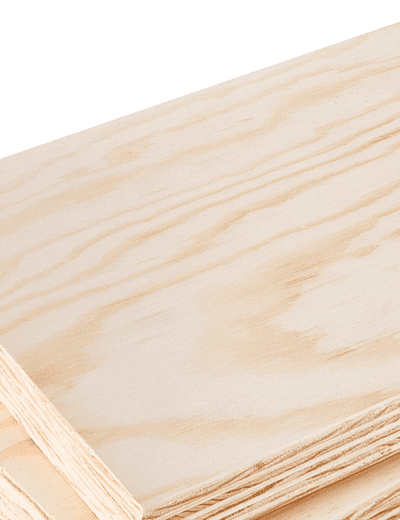

CB  Plywood

Plywood  Veneered panels

Veneered panels  Flexible plywood

Flexible plywood