Adhesive OC 14.50 for wood (D4)

Do you have any questions?

Contact us and we will help you| Product | Price for vnt (be PVM) | Quantity (vnt) |

|---|---|---|

|

Adhesive OC 14.50 for wood (D4):

20 kg

Package size:

20 kg

|

- |

Thank you, your request has been sent

PROPERTIES

Single component adhesive based on modified polyvinyl dispersion (vinyl acetate), waterproof class D4 according to PN-EN-204. At full strength, the seam has very good adhesion to wood surfaces under static as well as dynamic loading, and also has good initial adhesion. The adhesive has a certificate issued by IFT Rosenheim confirming class D4 according to the PN-EN 204 standard, as well as high thermal resistance: ≥ 7 N/mm2 according to EN 14257 (WATT`91).

APPLICATION

- natural wood for gluing during the manufacture of wood products for interior construction

- interior elements particularly exposed to moisture,

- exterior elements with appropriate surface protection

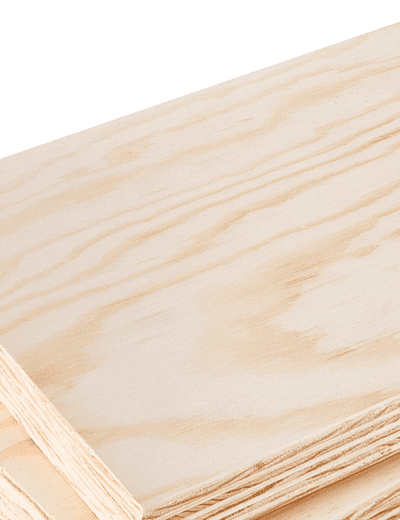

- bonding softwood

- bonding hardwood

- bonding floor panels

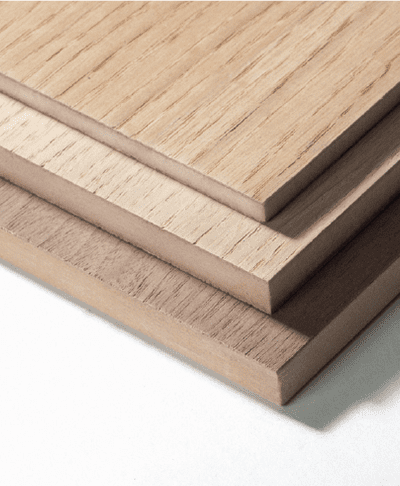

- bonding chipboard or fibreboard

- bonding plywood

- bonding other wood-based materials

- for use in cold pressing and manual bonding

- for use in hot pressing, chipboard and MDF

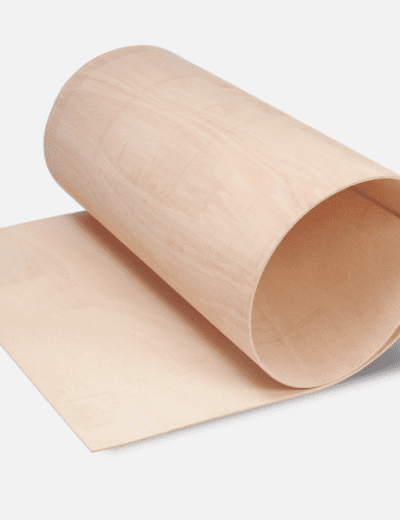

- for bonding plywood and laminates

- not recommended for external elements subject to intense exposure to moisture, such as doors or garden furniture, etc.

INSTRUCTIONS FOR USING THE ADHESIVE

Material preparation

The surface prepared for bonding must be dry, clean and free from dust, oil and grease residues which could reduce adhesiveness. Wood moisture should be 10 ÷ 14 [%]. The elements for gluing should be adapted to each other.

TECHNICAL DESCRIPTION

Dry matter content 51 ± 3 [%]

Brookfield RV adhesiveness 5,500 ± 1,500 [mPa·s]

PARAMETERS

pH approx. 3

MTTF approx. 6 [°C]

Durability after 25 min. Min. 4 [MPa]

Seam Colourless, flexible, does not damage tools, ageing resistant

Density 1.05 g/cm3

Application of adhesives

It is recommended to mix the adhesive thoroughly before use. The adhesive can be applied on one or both sides with a brush, trowel, spray bottle, applicator, hand roller or equipment (nozzles or rollers). The recommended amount of adhesive to be applied, depending on the type of base, is:

- surface bonding: 80 ÷ 120 [g/m2]

- mounting bonding: 120 ÷ 150 [g/m2]

- bonding wood for windows: 150 ÷ 200 [g/m2]

Discolouration

The adhesive does not affect the discolouration of the wood, but it is recommended not to use iron tools when working with the adhesive, as contact with wood containing tannin can lead to discolouration.

Open time

Open time: 3 ÷ 10 [min]. The open time depends on the type of wood, porosity, amount of applied adhesive, humidity and air temperature, adhesive and glued elements.

Bonding temperature

Use at 15 [°C] ÷ 30 [°C]. This affects the ambient temperature and above all the temperature of the materials to be glued and the adhesive itself.

Pressing

– pressing pressure

in the range 0,1 ÷ 1,2 [N/mm²] depending on the stresses present in the materials to be bonded. When applying adhesive manually, press the surfaces to be joined in such a way as to lead to the release of excess adhesive.

– pressing time

depends on the type of wood and its moisture content, temperature and humidity, as well as the amount of adhesive applied and the stresses present in the materials to be glued. Press the elements to be glued until durability is reached, when further processing or transportation is possible.

– suggested average pressing time

cold pressing over 20 [min]

hot pressing 2 ÷ 10 [min] (depending on the press temperature)

Good bonding results can be achieved when:

- Bonding process temperature is 15 ÷ 25 [°C]

- Relative air humidity 40 ÷ 70 [%]

- Wood moisture content 10 ÷ 14 [%]

- Quantity of adhesive applied 80 ÷ 200 [g/m2]

- Maximum open time 3 ÷ 10 [min]

CLEANING

Tools should be washed in water as soon as the work is finished. Do not allow the adhesive to dry. Remove the dried adhesive from the tools mechanically, before soaking in hot water (about 1 hour).

STORAGE

Store in original, tightly sealed containers at +5 to +30 [°C]. The product stored in such conditions retains its properties within 6 months from the date of manufacture.

Veneered panels

Veneered panels  Decking boards

Decking boards  Cladding boards

Cladding boards  Decking and cladding accessories

Decking and cladding accessories  Adhesive melt

Adhesive melt  Contact glue

Contact glue  Assembly adhesive

Assembly adhesive  PUR Glue

PUR Glue  PVA Glue

PVA Glue  Cleaners and other accessories

Cleaners and other accessories  Natural veneer

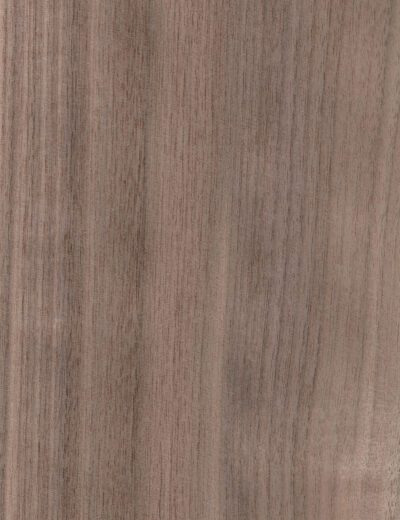

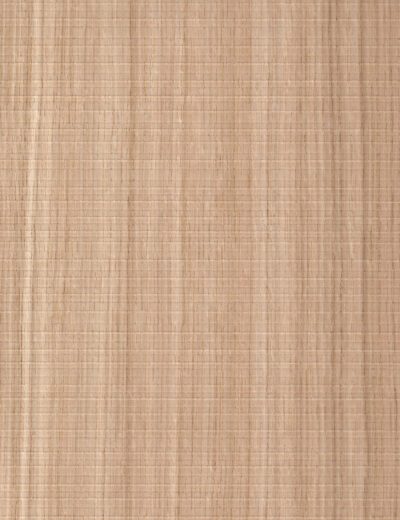

Natural veneer  Fine line veneer

Fine line veneer  South American wood spieces

South American wood spieces  African wood spieces

African wood spieces  American wood spieces

American wood spieces  Asian wood species

Asian wood species  European wood spieces

European wood spieces  Interior and exterior painted siding

Interior and exterior painted siding  Blockboard

Blockboard  MDF

MDF  CB

CB  Plywood

Plywood  Veneered panels

Veneered panels  Flexible plywood

Flexible plywood